Sequence viewing > Index - Cameras - lenses - optics - Resource - ©

Lloyd Godman

Film - Digital

Making

a PinHole Camera

Buying

a ready made pin hole camera

Professor

K's hand crafted pinhole cameras are innovative, educational,

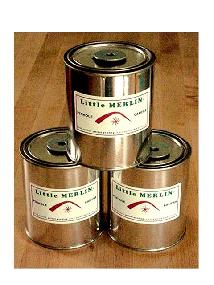

affordable and fun! MERLIN PINHOLE CAMERAS The MERLIN paint

can pinhole cameras are versatile, rugged and ready to go...

at very affordable prices. There are two camera sizes, gallon

& quart. They offer a lot of creative flexibility for an

increasing family of pinhole photographers... students,

teachers, working artists & scientists!

Buying

a pin a ready made hole camera |

Little

MERLIN pinhole camera |

Making

a pinhole camera can be simple or as involved as you wish

to make it.

As

the box needs to be light tight but also needs to have an entry

point to insert the film finding a suitable container with

a tight fitting lid allows a photographer to make one simply and

quickly. The container does not have to rectangular as do the images.

Remember the pinhole is projecting a circular image and some photographers

working with pinhole cameras play with the fall off of light at

the edge of the circle of illumination.

Once

you have found a suitable container ( this could be a made of tin

or an opaque cardboard), use a damp cloth to clean out any dust

or other material on the inside of the container.

As

light reflections inside the camera can have an adverse effect on

the image through fogging, spray paint the inside of the box. It

is also a good idea to do both the inside and outside of the lid

as well. Do this on old newspapers or where there will be no effect

from over spray. There is an art to spray painting with aerosol

cans:

it is best to not "soak" the insides of the oatmeal box with paint.

Spray in short bursts from several inches away, and constantly shake

up the can. Use as little paint as possible because you must wait

for the paint to dry before the pinhole can be installed, and because

excess black paint can become "dust" after it dries. Dust is the

photographer's worst enemy--it causes white spots on the finished

pictures which are hard to remove.

Carefully

cut the ends off of an aluminum soft drink can. Cut a "pinhole plate",

about 2 x 3 inches in size with rounded edges, from the aluminum can. The pinhole will

be drilled in the pinhole plate.

Making

the "Pinhole Drill"

Instead

of having a glass lens like "normal" cameras, the pinhole camera

uses a tiny hole, a needle-sized hole, to form the picture inside the camera.

The best size of pinhole for this camera body is one which is 1/100th

of an inch in diameter. There is a fine needle which is that size--the #16 beading needle. Because the needle

is small and difficult to handle, it must be glued into a handle to make a "pinhole

drill." As illustrated below, the drill is easy to make, and once

prepared, it can be used to make hundreds of pinholes in the soft aluminum stock cut from soft drink cans.

Mix

the epoxy in the cut-off end cap of a soft drink can. Place epoxy

in the mouth of the clothes peg and insert the needle until it protrudes about 1/4 inch. You may

have to cut the back of the needle off to make it fit into the clothes peg If the

needle protrudes more than about a quarter inch, it will easily

break off when used to drill pinholes.

The

finished "pinhole drill" should look like this: notice the 1/4 inch

length of the drill shaft.

Here you

see the delicate task of drilling a pinhole in the aluminum plate.

This is an important part of making a pinhole camera. It requires a delicate touch and a bit of patience. A fine pinhole will

result in sharp photographs and will last for centuries! Following are the steps for using

the "pinhole drill" to make a fine-quality pinhole lens.

Drilling

the Pinhole

Hold

the aluminum plate as shown and carefully press and rotate the "pinhole

drill" until the tip of the needle barely shows through on the other side.

When

you see the tiny needle point sticking through the other side, stop

drilling. Be careful to not push too hard on the "pinhole drill"--it must not stab completely

through the aluminum on the first try.

Carefully

sand the tiny hole made by the needle's tip. Then, drill again, carefully

and slowly until the hole is a bit larger. Sand the hole again on both sides. Drill

again, sand again. It should take three or four drilling and sanding steps to get a beautiful,

round 1/100th-of-an-inch-in-diameter pinhole "lens"! Finally, clean

the hole by running water through it and patting it dry with a clean paper towel. Try not to touch the hole

because oil and dirt from your fingers may partially fill the hole

and cause it

to take less sharp pictures.

installing

the Pinhole and Shutter

Installing

the pinhole into the box camera body.

Before

placing the pinhole plate inside the camera body, put electrical tape

on two sides and make a circle of epoxy glue around the pinhole, without getting any

glue on the hole itself.

Then

carefully place the pinhole plate inside the camera so that the pinhole

is in the middle of the cut-out opening. Press the pinhole plate inside the camera for a few

minutes, until the epoxy glue thickens. A tight seal around the pinhole plate prevents

any light from leaking into the camera. The other place where light

likes to leak into the camera is around the lid.

Making

the Shutter...

From

a file folder, measure and cut out two strips, 1 inch by 7 inches

each. These strips will become the shutter guides. Cut two 10-inch strips of electrical tape

and stick them over the shutter guides, leaving about 1 1/2 inches of tape overhanging

each end of the shutter guides.

The

shutter is made from two parts. Cut a 1 1/2 x 2 inch piece from the

file folder. Also cut from either the file folder or from heavier cardboard (such as a

breakfast cereal box) a strip 3/4 x 5 inches long. Fold the strip

in half, then bend out the two "legs" as above, put a spot of glue inside the handle and wrap electrical tape around

it. Finally, glue the shutter handle onto the shutter slide. Hold the shutter handle down

until the glue hardens. The result: a pinhole shutter!

Place

the shutter guides on the camera and align them over the pinhole box.

Stick them down gently at first because adjustments will become necessary to allow

the shutter to slide easily. Unstick one end of the shutter guides and insert the

shutter. Re-align the shutter guides as necessary to allow the shutter

to slide easily (but not too easily!) while uncovering and covering the pinhole. Ready for the last step?

Slide

the shutter open and, with an inkpen, make a visible mark above and

below the pinhole. These marks allow you to line up the pinhole shutter's handle directly over the pinhole. This makes the

shutter handle an aiming device which will be useful when you take pictures with your

new pinhole camera.

Finished!

Notice

the shutter handle sticking out from where the pinhole is located

beneath the

mark on the shutter guide. The smiling Quaker now is gagged; only

his friendly eyes remain visible. This completes building the pinhole camera. Now

it is time to set up a darkroom. Pinhole cameras must be loaded with

film in a darkroom, and the pictures

taken with them can only be developed in a darkroom. The drugstore

wouldn't know what to do with film exposed in an oatmeal-box pinhole camera: this is a do-it-yourself process. Also,

be sure to remember to strap on the lid with a pair of rubber

bands before going outside into the bright sun. Most light leaks come

from the camera lid.

Want to learn more? - do a workshop or one on one with Lloyd Godman

|